Dataloggers

- Allmetra AG

- Accessories & Components

- Dataloggers

In almost all industries, the acquisition of measurement data and its analysis form the basis for a wide range of optimization and decision-making processes. Dataloggers collect and save the data required for this. These are versatile, powerful, yet inexpensive data acquisition devices that process analog, digital, and other types of variables at high speed and resolution. Whether you want to save the measurement data from temperature-, humidity-, or force sensors, our dataloggers offer the best way to do this.

Models:

- Industrial multichannel datalogger

- WLAN datalogger

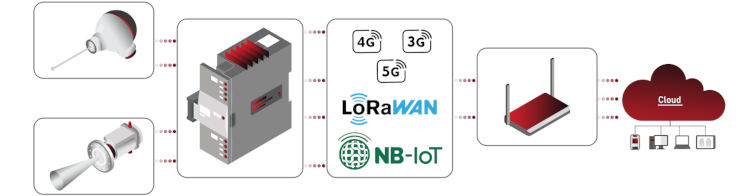

- 3G / 2G multi-channel datalogger

- Micro datalogger for temperature and humidity

- USB temperature datalogger

- Micro datalogger for analog signals

Specifications:

Inputs / outputs and interfaces:

- Universal analog input channels (thermocouples, V, mV, mA, Pt100 and Pt1000)

- Digital I/Os (individually configurable as input or output)

- Relay outputs

- Pulse counter

- Virtual channels for math functions

- RS485

- Ethernet

- Wi-Fi 802.11 b / g / n

- Communication with SCADA or cloud system: MQTT and Modbus-TCP protocol

Areas of application:

- Environmental and food technology

- Automobile

- Water and sewage

- Chemicals, oil & gas

- Textiles

- Energy

- Agriculture

- Mining

Dataloggers consist of a programmable microprocessor, one or more cables for connecting the data source, at least one interface, and a storage medium. The data is recorded internally or externally via a manufacturer-dependent interface.

The following interfaces allow the data to be integrated into a controller and transmitted over a large range. The most common interface variants in the industrial and machine sectors are:

- RS232

- RS485

- CAN

- USB

- Ethernet

Any external sensors, devices or machines can be connected as data suppliers via connections like USB, Bluetooth, WLAN, D-Sub, or industrial terminals. These forms of access usually also make it possible to configure the datalogger for an area of application. Depending on the desired measured variable, dataloggers have one or more channels in order to be able to connect several sensors to them at the same time. The storage rhythm depends on the specific use. The storage process always takes place fully automatically at precise time intervals, or at the moment of data generation.

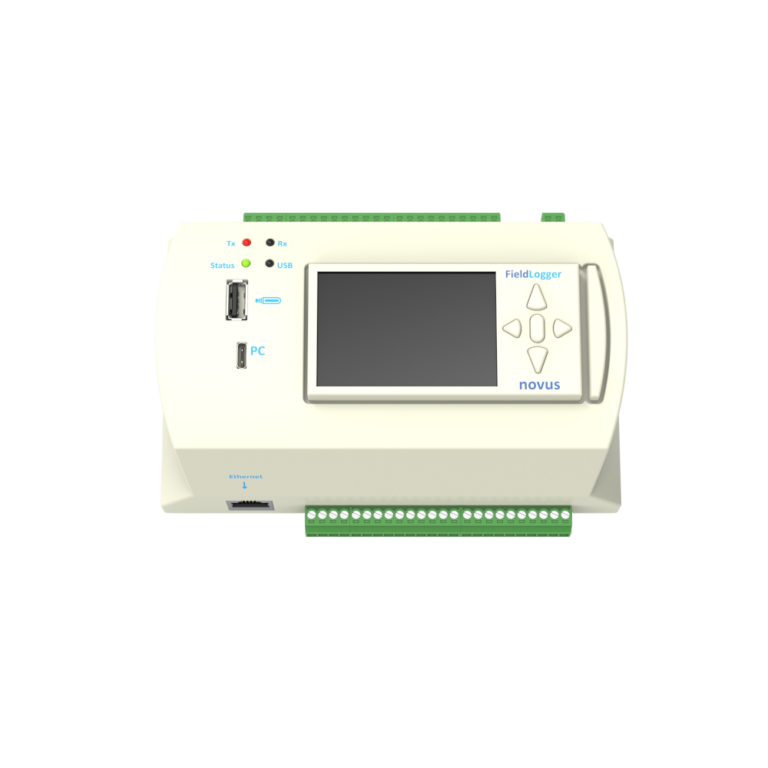

The datalogger presented here has configurable analog inputs that can be used for thermocouples, resistance thermometers based on Pt100 and Pt1000, as well as voltage and current signals. In addition, two relay outputs and eight digital ports can be configured individually as inputs or outputs. Up to 128 math channels are available for operations on the measured values. In addition, the datalogger can recognize up to 32 alarm events and send corresponding output activations, e-mails and SNMP traps.

The RS485 interface of the datalogger can be operated as a Modbus RTU master or slave. As a master, it can read and log up to 64 external channels. A 10/100 MBps ethernet interface enables access via browser (HTTP), FTP (server and client), SNMP, sending e-mails (SMTP) and Modbus TCP. The 512K basic logging memory used for data storage can be expanded using an SD card. An exclusive color HMI can also be connected or installed remotely for local display or configuration.

Are you looking for a customized solution for the acquisition and storage of measured values and their preparation for analysis? Then Allmetra is the right partner for you. Our datalogger can be used not only for the sensors we produce, but also for sensors from other manufacturers. Get in touch with us and benefit from our know-how, customer proximity through our global sales network, and short delivery times thanks to fast worldwide airfreight.

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.