Digital displays

- Allmetra AG

- Accessories & Components

- Digital displays

Without a display, the measurement results determined by sensors are invisible. Digital displays, technically also referred to as process displays, make visible the information transmitted to them in the form of numbers, characters and/or letters.

In contrast to many other forms of display, powerful displays with fast response times and self-illumination are easy to read even in poor lighting conditions and from a great distance. This also applies to our universal process displays, whose 17 mm high displays offer a clear view and thus make them easier for operators to read.

Models:

- Universal process indicator

- Loop-fed display

- Flow indicator

- Display for weighing modules

- Cooling and heating temperature

- Differential temperature

- Humidity

- Programmable timer

Specifications:

Inputs / outputs and interfaces:

- 0… 20 mA

- 4… 20 mA (preferred)

- 0… 10 V

- 5 Vdc logistician output

- Alarm

- RS485

- Relay

Areas of application:

- Environmental and food technology

- Automobiles

- Water and sewage

- Chemicals, oil & gas

- Textiles

- Energy

- Agriculture

- Mining

The most commonly used type of digital display is the seven-segment display, which is also used in digital watches and pocket calculators. This can display the digits from 0 to 9, plus a large number of letters, with the help of up to seven individual lines. Compared to normal fonts, the representation is abstract, so not quite perfect. This is particularly evident with the digits 4 and 7. In daily life, however, this is hardly noticeable due to the widespread use of seven-segment displays, which people have become used to.

Since the vast majority of systems today use data width of at least 8 bits, most display elements have a point as the eighth “element”. This is usually located on the baseline to the right of the lowest segment. It is controlled via the eighth data bit and is primarily used as a decimal separator. Specialized digital displays for the visualization of temperatures also have a degree symbol in front of the last display element, which is used to display the unit (C for Celsius or F for Fahrenheit).

Today, the segments on most digital displays are made up of light emitting diodes (LEDs) or liquid crystal displays (LCDs). They are controlled via integrated seven-segment decoder circuits (ICs) that convert binary-coded numbers (4 bits) into 7 bits to control the seven segments. In the meantime, programmable microcontrollers are partially replacing the ICs in smaller displays. To do this, however, it is necessary to reduce the number of necessary I/O connections on the microcontroller with a BCD-to-7-segment decoder.

Our universal process indicator is a seven-segment display. With six digits for high-resolution variables and a 17 mm high display, it offers everything required to display measured values in industrial environments. It works with a fast sampling rate and ensures powerful visualization and response. This makes it ideal for use in areas with high process dynamics.

The timer function on our digital displays offers a wide range of possible actions, such as alarms for safety interlocking. With linearized inputs for up to 30 points, the displays are also fully compatible with customer-specific signals and sensors from other manufacturers. Both their non-flammable housing and electronic robustness meet all the requirements of the most important world-class approvals for use in the industrial sector.

Contact us today and benefit from customized solutions and short response times thanks to our global sales network and fast worldwide airfreight service that ensures on-time delivery.

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

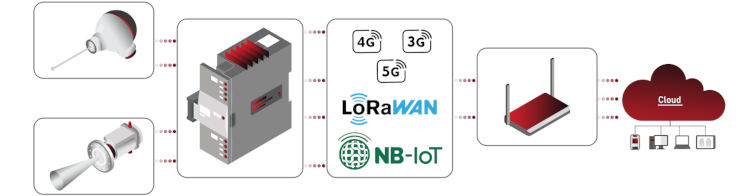

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.