Thermowells

- Allmetra AG

- Accessories & Components

- Thermowells

In many areas of application, the process conditions are so rough that temperature sensors cannot be inserted directly into the medium. This is the case, for example, when there are high flow velocities, higher pressures, or aggressive media. This is why screw-in and weld-in thermowells have been developed, within which sensors are optimally protected from external influences. Thermowells are also used when a thermometer has to be replaced without interrupting a process. We can offer you an extensive portfolio of thermowells that meet all quality and process reliability requirements.

Due to the multitude of possible uses, thermowells are available in a wide variety of designs. An important selection criterion is the type of process connection. Thermowells can be screwed in with a thread, welded in, or integrated into the process with a flange. To ensure exact temperature measurement, the thermometer and thermowell must fit together perfectly.

Multi-part thermowells consist of a tube that is closed at the top with a welded-on bottom piece. One-piece thermowells, on the other hand, are made from solid rod material. The latter are mainly used in the case of high process loads and strong chemical stresses. Internationally and in the petrochemical industry, one-piece thermowells are used almost exclusively. They have also been proven in process engineering and apparatus engineering.

Multi-part thermowells are suitable for low to medium process loads. Thermowells for insertion, welding, or with a flange can be found, for example, in the chemical industry, in apparatus engineering, and in process engineering. Multi-part thermowells with flanges are also used for high chemical stresses. Certain variants are used in incineration plants, boilers, ovens and reactor vessels, for example in the chemical industry, petrochemicals, or in the offshore sector.

Thermowells must be long enough for the medium to flow against the temperature sensor. This is usually ensured when the tip of the thermowell is in the middle third of the line. A minimum installation length of 60 to 100 mm can be assumed for mechanical thermometers. Electric thermometers require at least 30 to 50 mm. The maximum installation length for one-piece thermowells is 1,000 to 2,000 mm, depending on the model. Longer one-piece thermowells can also be created by welding several individual pieces together. In the case of multi-part thermowells, maximum lengths of up to six meters are possible.

Another distinguishing feature of thermowells is the shape of the shaft. This can be straight, conical or stepped. The conical shaft shape is most often used, which guarantees a short response time simultaneously with high strength. Multipart thermowells usually have a straight shaft. When it comes to the material, the choice is predominantly stainless steel. In the case of particularly demanding loads, special materials such as highly corrosion-resistant nickel-molybdenum or nickel-copper alloys can be used.

Our offer includes thermowells a wide variety of designs made of different materials for applications such as:

- Furnace construction

- Boiler construction

- Pressure lines

- Food industry

- Chemical industry

In order to optimally adapt thermowells to their field of application, it is possible to do special calculations of the pressure load capacity, depending on temperature, flow and medium. Naturally, you can use thermowells not only for sensors manufactured by us, but also for your sensors from other manufacturers.

Are you looking for a tailor-made solution? If so, you’ve come to the right place. Contact us via our global sales network and let us advise you personally.

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

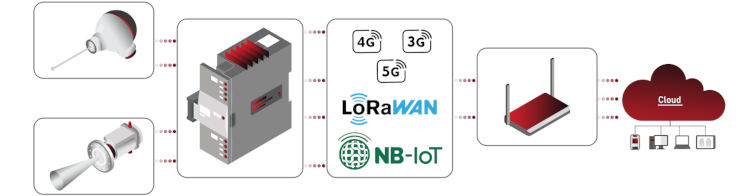

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.