Transmitters, analog and digital

- Allmetra AG

- Accessories & Components

- Transmitters, analog and digital

Temperature measuring points consist of a temperature sensor and a transmitter, also called a measurement transducer. The latter converts the input variable provided by the transmitter into a processable output variable, e.g. B, into a standardized, temperature-proportional current signal. In contrast to the small, sensitive output signal of the sensor, this can be transported over longer distances without interference, and thus ensures significantly higher process reliability. We can also provide you with a wide variety of transmitter types that are suitable for use in potentially explosive areas, including branded transmitters from Rosemount and INOR.

Models

- Temperature

- Pressure

- Fill level

- Force

- Level

- Ultrasonic

- Electrodes, PH

- Acid, alkali and salt concentration

- Conductivity

- Isolators & isolation transmitters

Specifications:

Inputs / outputs and interfaces:

- 0… 20 mA

- 4… 20 mA (preferred)

- 0… 10 V

Areas of application:

- Environmental and food technology

- Automobile

- Water and sewage

- Chemicals, oil & gas

- Textiles

- Energy

- Agriculture

- Mining

Until the introduction of transmitters, the raw measured values from temperature sensors reached control stations by cable. Once there, they were transformed and processed. This type of transfer had the disadvantage that the line resistance increased with the length of the cable, and thus falsified the measurement. This led to inaccurate measurement results. Today this form of transmission is only used in special cases, for example if the ambient temperature in the area of the sensor is too high, or if the place where it is installed is too narrow. These tasks can also be done via a transmitter to a carrier rail mounting in the control cabinet.

Head transmitters built into the connection head of the thermometer have become established in almost all other applications. One design often used for this purpose is a 2-wire transmitter, which draws its energy from its own connection cables. Their usual output current of 0 – 10V, 4 to 20 mA, and I2C corresponds to the measurement signal and is basically temperature linear. Both resistance thermometers and various types of thermocouples can be connected to the transmitter input.

Modern transmitters let you not only collect measurement values digitally, but also configure the devices. This involves, in addition to the selection of the sensor input and the measurement range, the storage of measurement point identifications such as MSR descriptions and TAG numbers, as well as the adaptation of the measurement signal using a specific sensor characteristic or an offset.

Another feature of modern temperature transmitters is their diagnostic functionality. The devices don’t just convert the value of the sensor into a signal suitable for processing. At the same time, they can check relevant parameters in the background, such as the internal electronics temperature, the supply voltage, and the lead resistance. If errors occur, the transmitter sends a corresponding signal, enabling among other things, the early detection of sensor breakages and short-circuits, supply-side effects, and when using dual sensors, the drifting of a measured value.

Whether analog or digital, our Profibus and HART-compatible head and rail transmitters provide the right solution for temperature measurements in process industries. In order to adapt them perfectly to your needs, we will program the transmitters according to your data. On request, we will issue you with a calibration certificate in accordance with EN 10204-2.1. Different versions are available for use in potentially explosive areas of application with the following approvals:

- ATEX

- NAMUR

- FM, CSA

Naturally, you can use our transmitters with inexpensive 2-wire connection technology not only for the resistance thermometers and thermocouples we manufacture, but also for sensors from other manufacturers.

Contact us for a tailor-made solution and benefit from our over 50 years of experience in the field of measurement technology. We guarantee customer proximity and short response times through our global sales network. Our fast air freight service ensures flawless, on-time deliveries.

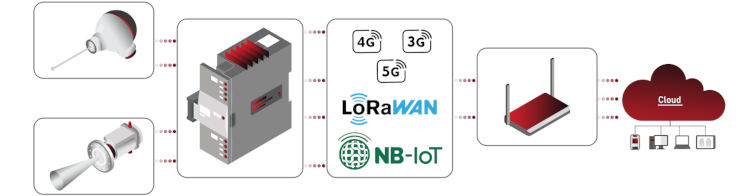

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.