DMS strain gauges

- Allmetra AG

- Products & Production

- DMS strain gauges

Mechanical and thermal effects can cause materials to deform. An example of this is elongation, the relative change in length of a component due to a force, heat or cold. Deformation due to elongation, as well as compression, can be measured with the help of so-called strain gauges, or DMS for short. These are metallic-electrical sensors whose function is based on changes in resistance due to alterations in length or width.

Models:

Applications with Y, M, C, KFU, and customer-specific DMS series

Specifications:

- Temperature range: -269 °C to +350 °C

- Applicable component materials: aluminum, steel, plastic, ceramic, etc.

Types of application:

- Bonding and circuitry as quarter-, half- or full bridges for torsion, bending, tensile and compressive force measurements

- Strain measurements in one direction

- Determination of expansion processes

- Stress analysis of materials with high fatigue resistance

Areas of application:

- Maritime / shipbuilding

- Medical technology

- Civil engineering and construction

- Research & development

- Mechanical engineering

- Aviation

Our portfolio includes various types of strain gauges for high-precision static and dynamic measurements. We would be happy to produce customized solutions for you to meet your specific requirements.

There are different types of strain gauges, but the same basic structure generally applies. The centerpiece is a measuring grid that is applied to an insulating carrier material. Paper, fiberglass fabric, or plastic film serve as a carrier, while wire, etched film or vapor-deposited film made of a semiconductor (mostly silicon) or metal (mostly constantan or NiCr compounds) serve as a measuring grid. The shape of the measuring grid is based on the application.

The most common types of strain gauges are foil strain gauges that are glued to the component to be measured. These have a measuring grid film made of three μm to eight μm resistance wire applied to a plastic carrier (epoxy resin, acrylic resin, phenolic resin, or polyamide), or etched into the film. Most strain gauges with this type of construction have an additional film on their upper side, which mechanically protects the measuring grid. If strain measurements need to be made in several dimensions, so-called rosette strain gauges are suitable. These have several sensors arranged one above the other on a carrier film.

In order to measure strain, electrical circuits like a Wheatstone bridge are used. This is made up of four resistors that together form a circle or ring. Depending on how many of the resistances are actively measured, we use quarter-, half- or full bridges. Bridge circuits offer advantages in strain measurement, since a strain gauge built into an electrical circuit acts like an ohm resistor.

Together with you, we will put professional DMS applications on your components in line with your technical specifications. Applications with types Y, M, C and KFU can be supported, as well as customer-specific strain gauge series. Temperature ranges from -269 °C to +350 °C can be used. When it comes to component materials, you can choose from aluminum, steel, plastic, ceramic, and others.

Our strain gauges are used in a wide variety of industries. The most important are:

- Automotive

- Maritime and shipbuilding

- Medical technology

- Civil engineering and construction

- Mechanical engineering

- Research and development

- Aviation

We have bonding and circuitry as quarter-, half- or full bridges for measuring torsion, bending, tensile or compressive force in our program, as well as strain gauges for determining expansion curves, expansion measurements in one direction, and stress analyses of materials with high fatigue resistance.

If you need special configurations, we can adapt our strain gauges to your needs in the following ways:

- Changes to the measuring grid arrangement

- Manufacture of user-specific measuring grids

- Several strain gauges on one carrier

- Customer-specific cable lengths and materials

- Special shapes or cut-outs for adaptation to the geometry of the measured object

- Additional connection points or freely definable solder pad positions

Together with you, we will find an individual solution that perfectly matches your specifications and requirements. Our worldwide fast airfreight service ensures that your strain gauges arrive safely and on time. Get in touch with us and let us advise you personally.

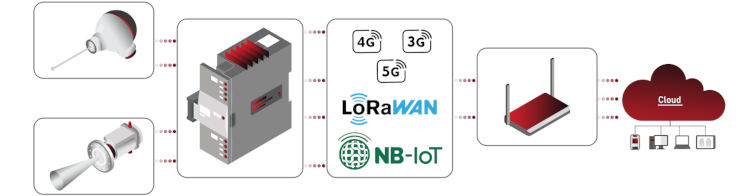

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.