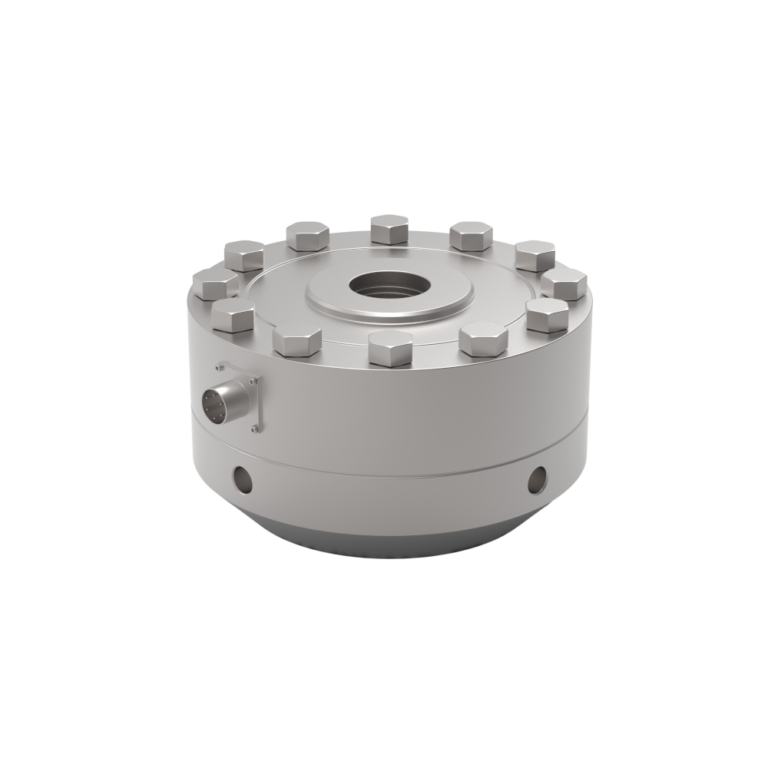

Force sensors

- Allmetra AG

- Products & Production

- Force sensors

In order to achieve high-quality results in areas including industry, logistics, mining, and mechanical engineering, reliable force and weight measurements are required. This is why different types and forms of force sensors have been established over the years. Their operating principle is based on the law of gravity, according to which every object exerts a certain force on its base. We can offer you the right force sensor for every imaginable measuring task, with excellent accuracy and a wide range of mechanical adaptation options.

Models:

- Load cells

- Miniature or S-shaped sensor

- Weighing modules

Specifications:

- Nominal force: <1kN, 1-100 kN, 100-500kN, over 500kN

- Push force, tensile force, and tensile & compressive force

Types of application:

- Industrial process control

- End-of-line tests in production lines

- Monitoring of machine parts

- Scale construction, e.g. platform scales, postal scales, table scales, container and dosing scales

- Fill level measurement

Areas of application:

- Automobile

- Aviation and aerospace

- Railways

In order to achieve high-quality results in areas such as industry, logistics, mining, and mechanical engineering, reliable force and weight measurements are required. This is why different types and forms of force sensors have been established over the years. Their operating principle is based on the law of gravity, according to which every object exerts a certain force on its base. We can offer you the right force sensor for every imaginable measuring task, with excellent accuracy and a wide range of mechanical adaptation options.

Force (F) is a product of the mass and the acceleration of a body. It is a vector quantity that can act in all three directions of space. It can be determined using various physical effects, whereby the force is in a defined relationship to another variable, for example:

- Tensile and compressive forces

- Elastic deformation (e.g. change in length, expansion)

- Piezoelectricity

- Vibration

- Electrical resistance

The most common measurement of force is via the elastic deformation of solids. Mechanical, electrical and hydraulic force sensors are used here.

Mechanical force transducers are particularly suitable for static individual measurements and for areas where low measurement accuracy and the on-site display of measured values are sufficient. Hydraulic force transducers are usually the best choice for medium measurement accuracy and rough use. The display is on a pressure indicator attached directly to the sensor. The highest accuracy is achieved by electrical force transducers, which are also suitable for dynamic measuring tasks and robust operations.

A distinction is also made between single-component and multi-component force measurement. Single-component sensors only measure the force in one direction. To do this, the direction of measurement must match the direction of flow of the force. With multi-component types, measurement is carried out in two or three spatial directions.

We manufacture the following sensor models for force and weight measurement:

- Load cells

- Miniature or S-shaped sensors

- Weighing modules

With regard to the nominal force, we can offer you the following specifications:

- < 1 kN

- 1 to 100 kN

- 100 to 500 kN

- > 500 kN

The smaller the nominal force, the more sensitive the measurement. You also have a choice of compressive force, tensile force, and tensile and compressive force.

It is also possible to order a transducer with so-called TEDS. A small chip is built into the transducer or the cable, on which the exact details of the test protocol are saved. Suitable measurement amplifiers can read this and automatically adjust themselves accordingly.

Our force sensors offer you optimal monitoring solutions for industries such as:

- Automobile manufacturing

- Aviation and aerospace

- Railway rolling stock manufacturing

Our products are suitable for industrial process control as well as for end-of-line tests in production lines, the monitoring of machine components, and fill level measurements. Another field of application is the manufacture of scales. Here Allmetra force sensors are used in platform scales, bench scales, postal scales, as well as container and dosing scales.

Our force sensors will help you to make your systems and machines more efficient, and secure your production and service quality. Our sole aim in developing and producing our sensors is to offer you reliable measurement technology that is adapted to your individual needs and fully meets your requirements.

Thanks to our global sales network, we are always close to you and can therefore guarantee first-class support, including personal advice. Contact us today for a tailor-made solution.

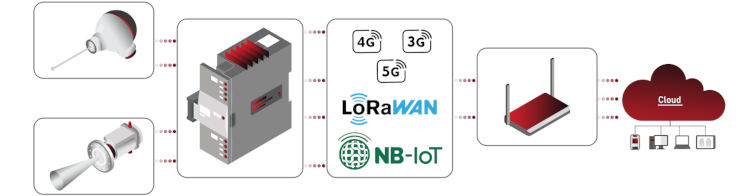

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.