Infrared sensors

- Allmetra AG

- Products & Production

- Infrared sensors

Infrared sensors react to infrared radiation. This is electromagnetic radiation with a wavelength between 780 nm and 1 mm, which is invisible to the human eye. However, humans can perceive its warming effect through the skin. This has led to the term “thermal radiation”, which is often used synonymously. We will develop and produce pyrometers or infrared thermometers for you that are ideally suited for point and surface temperature measurement. Thanks to a wide variety of configuration options, these can be used in almost all areas of application.

Models:

- Pyrometer

- Video pyrometer

- High-performance series

- IR cameras (compact and precision lines)

Specifications:

- Measuring range from -50 °C to +3000 °C

- Spectral range from 1 μm to 14 μm (different depending on the application)

Detector:

- Thermopile, InGaAs, FPA, CMOS

Types of application:

- Lamination of vehicle interiors

- Function test of assembled circuit boards

- Blown film extrusion

- Injection molding temperature measurement

- Inductive heat treatment of metals

- Early fire detection

- Workpiece control during drop forging

- Temperatures for sterilizing glass bottles

Areas of application:

- Automotive industry

- Early fire detection

- Medicine / life sciences

- Glass industry

- Maintenance / servicing

- Plastics processing

- Metal industry

- Solar and semiconductor industries

There are two basic types of infrared sensors:

- Passive sensors that can only receive infrared rays, and

- Active sensors that emit thermal radiation themselves and measure its reflection

The former are used to measure the thermal radiation emanating from an object or living being. This enables different actions to be set in motion, such as turning on lights or triggering an alarm. Active infrared sensors are more common in industrial environments. There they determine, for example, whether an object is in a certain position on a conveyor belt, or they enable contact and non-contact temperature measurements. Further fields of application include quality control of production processes, industrial image processing, as well as circuit board development (electronics development).

Passive infrared sensors consist of four components:

- A transmission medium (atmosphere, vacuum, optical fibers)

- Optical lenses for focusing the IR rays (mostly made of quartz, silicone, polyethylene, germanium, or calcium fluoride, in combination with mirrors made of gold or aluminum)

- An infrared light-sensitive material to detect the IR radiation (e.g. lithium tantalate (LiTaO3))

- Signal processing or amplification, to amplify the signals received from the detector

Active infrared sensors additionally have their own infrared source. This must have a temperature of over 0 Kelvin in order to be able to generate thermal radiation. In most cases, infrared lasers, LEDs, or specific IR wavelengths are used for this.

Our product range of infrared sensors includes the following models:

- Pyrometer

- Video pyrometer

- High-performance series

- IR cameras (compact and precision lines)

The measurement range can be specified from -50 °C to +3000 °C, and the spectral range from 1 µm to 14 µm. In terms of detectors, our selection extends from thermopiles to InGaAs and FPA to CMOS. Our temperature sensors and thermal imaging cameras thus enable flexible and cost-saving use in a wide variety of industries such as:

- Automotive

- Glass

- Metal

- Plastics processing

- Early fire detection

- Medicine / life sciences

- Maintenance / servicing

- Solar and semiconductor

Whether during lamination of vehicle interiors, in blown film extrusion, or injection molding temperature measurement, infrared sensors ensure reliable operation and accurate readings. They can be used for functional testing of assembled circuit boards as well as for workpiece control in drop forging, or for inductive heat treatment of metals. Are you looking at infrared sensors for early fire detection or for temperature control in the sterilization of glass bottles? Then you’ve found the right partner in us.

Is your area of application not yet listed? Simply get in touch with us. We’ll work with you to develop a tailor-made solution.

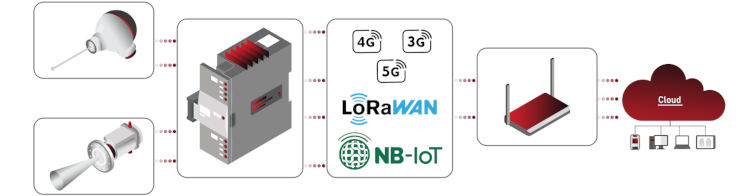

Allmetra’s measurement chain

Products & Production

During our decades of experience, we have found the perfect balance between in-house production and using our partners’ plants. Always with the aim of delighting our customers with the best possible solutions.

Accessories & Components

We have built true partnerships with our suppliers through our many years of doing business together. We only work with quality-conscious, highly qualified suppliers.

Services & Solutions

We keep an eye constantly on the future, which we see filled with expert advice, technical support, and developments ranging from a wide array of sensors up to customized IoT / IIoT software solutions.